Mold design

TSD Mold engineering team has rich experience in design, intense sense of responsibility and full design checking procedure, we have confidence to offer high-level mold designs to our customers. At a time, we pay more attentions on customer’s feedback and comments to enhance our engineering level.

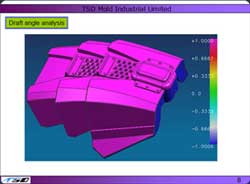

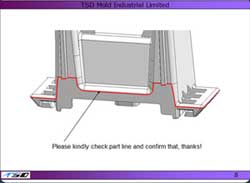

Our design principle is to guarantee the high efficiency, safety and long lasting of the tools. That’s even in quotation phase, we will also give our customers professional suggestions on mold steels and standard components basing on product requirements. What we do is to reduce customer’s cost. In mold step, we’ll do product analysis comprehensively and pass our report to customers for discussion, like parting line, gate and ejection location etc. At the same time, we’ll start to design the 2D drawings for customer’s approval on basic information and to reduce the design lead time. Finally, our team will use UG or Pro/E to begin 3D design for easy customers to confirm the drawings with a real image, drop mistakes as well.

We not only lay stress on mold structure reliability and durability, but also cooling and other tooling details. Our aim is to shorten the manufacturing lead time and let customers get more economic benefit. If necessary, we can offer mold flow report also.

|

|

|

| Draft Angle Analysis | Part Line | Ejector Position |

Mold Type Introduction

TSD Mold has rich experience in the engineering and building of all types of plastic molds, including

• Precision mold

• Middle & big mold

• Insert-molding

• Unscrew mold

• Over mold

• 2 shots

• Hot runner mold

|

|

|

| 2D Construction | Mold Flow Analysis | Full 3D Design |